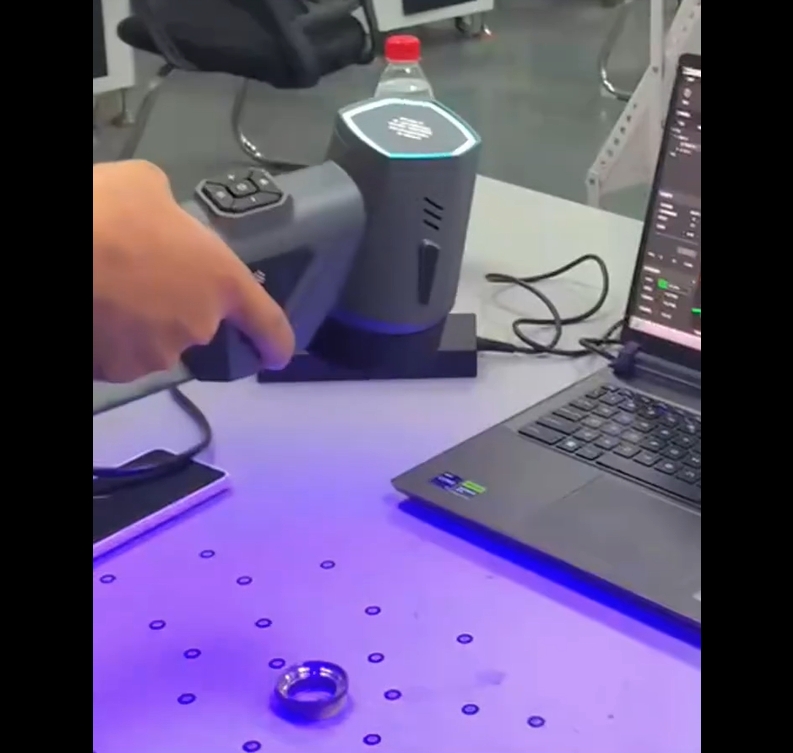

In the industrial field, the inspection and maintenance of various equipment is the key to ensure the normal production. 3D scanning technology provides a new means for the detection and maintenance of equipment. Through the 3D scanning of the equipment, the detailed 3D data can be obtained and the digital equipment model can be established.

During the operation of the equipment, the equipment can be scanned in 3D regularly, compared with the original model, and the deformation and wear of the equipment can be found in time. This can provide an accurate basis for the maintenance and maintenance of the equipment, extend the service life of the equipment, and improve production efficiency.

At the same time, 3D scanning technology can also be used for equipment transformation and upgrading. For the transformation of old equipment, 3D scanning can obtain the three-dimensional data of its existing structure, which provides the basis for the design of new parts and improvement schemes. This can effectively improve the performance and adaptability of the equipment to meet the changing production needs.